Avoid Common Wire Rope Damage

Wire rope has many applications—today the focus is on Wire Rope slings. Read on for tips from our Brampton rigging experts to inspect your wire rope sling and prevent common wire rope damage, so your wire rope slings have a long life.

Wire Rope: basic components

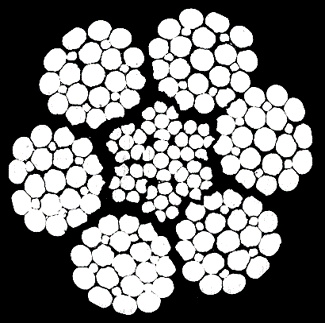

A piece of wire rope has three main components. Individual wires that make up each strand, the strand itself and finally, the core it’s built around. (See figure 1). The core is typically composed of fibre core (FC) or steel wire core, called independent wire rope core (IWRC). The steel core increases strength by 7% and the weight by 10%, which provides more support to the outer strands than fibre cores. Steel cores resist crushing and are more resistant to heat.

The design factor of wire rope tells you the ratio between minimum breaking load of the rope and the working load limit (WLL).

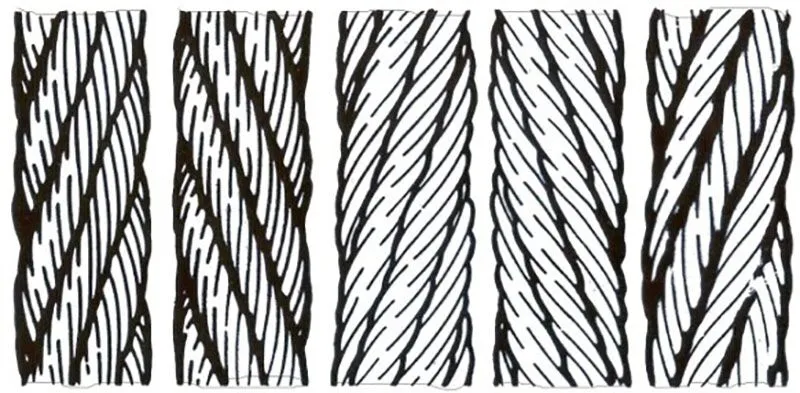

Wire Rope Lay Patterns (L-R) Right Lay/Ordinary Lay, Left Lay/Ordinary Lay, Right Lay/Lang’s Lay, Right Lay/Reverse Lay (Cross Lay)

Figure 1

Wire Rope Sling Inspection: what to look for

It’s important to inspect your wire rope sling before use to prevent common wire rope damage—but also for safety. Wire rope slings don’t normally pass around a pulley, therefore it’s important to look out for wear from the environment, like:

- Abrasive dust, little to no lubricant

- Normal wear-and-tear

- Corrosion (look for discolouration, lack of flexibility and rough to-the-touch feel)

- Abrasion

- Thermal damage (over-heating)

- Termination failures

When inspecting the wire rope itself, look for wear at the crown, the core strands and inter-strand wear. Check for kinked, damaged or broken wires. This kind of damage is often caused by slinging a previous load incorrectly—if excessive wear is present, it may be best to look at how wire rope slings are used on the worksite. Keep reading for tips to avoid common wire rope damage and wear and tear on slings.

Wire Rope Sling Don’ts:

- Don’t join slings by threading eyes;

- Don’t pull loops in your sling or use a knotted/kinked sling;

- Don’t tie knots in sling legs to reduce length;

- Don’t overload the sling;

- Don’t pull from under a load;

- Don’t lift a container with only two slings;

- Don’t place slings near welding/cutting operations;

- Don’t force the eye to open more than 20° (this places undue tension on the ferrule);

- Don’t stand under a load;

- Don’t land the load directly on the sling;

- Don’t wrap a wire rope around a hook—this kinks the wire and ruins the sling.

Wire Rope Sling Do’s:

- Always use a shackle with at least the same SWL to join slings together;

- Use suitable storage/packaging;

- Minimum radius sling can be bent is 3 times diameter of sling wire rope.

Most damage to wire rope slings is caused by unnecessary chaffing against the load, ground or nearby objects. Avoid abrasion and don’t place your sling in contact with adjacent structures, don’t drag your wire rope sling from under a load, and avoid double-choke hitching to prevent common wire rope damage.

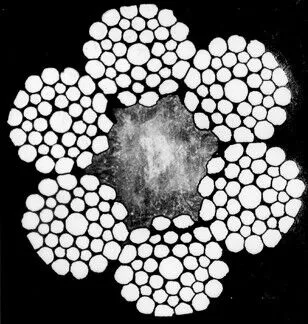

Wire rope sling corrosion is a major cause of deterioration, and is caused by poor storage, exposure to weather and corrosive chemicals. Thermal damage happens when the operating temperature is too high, electric arching was used during welding or if the sling was exposed to lightening. External wear can typically be seen from the outside, however, it’s more difficult to asses internal damage—the rope must be opened up. See figures 2 and 3 for examples of internal wire rope corrosion.

Internal wear is most affected by pressure and friction. Factors that affect internal wear include:

- Level of rope tension

- Bending ratio

- Bending frequency

- Lack of lubricant

- Tension fatigue (affected by degree of tension)

Wire Rope termination: what to look for

- Wire breaks

- Corrosion

- Reduction in rope diameter

- Unusual rope movement

- Evidence of rope end

- Evidence of any incorrect fitting

- Evidence of any component wear

- Avoid Common Wire Rope Damage: battening down

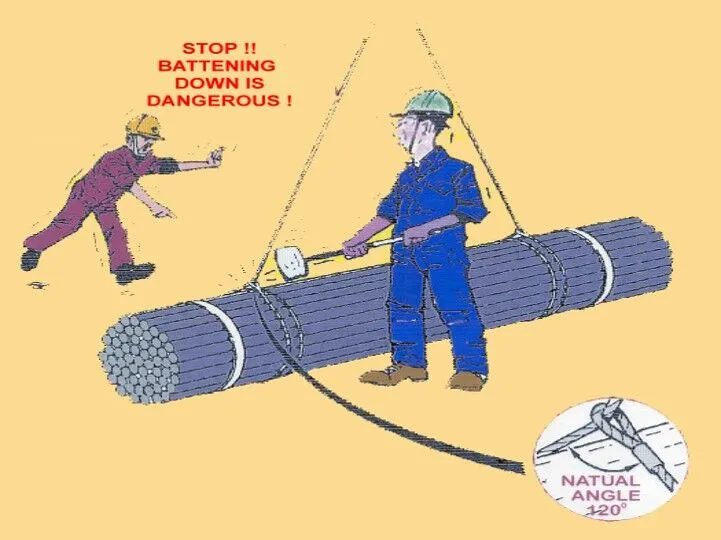

When a rigger strikes the eye of a sling in a choke hitch to force the bright closer to the load in an attempt to ‘make it more secure’—this is known as battening down (not to be confused with a batten from theatre rigging), and is actually very dangerous. The bight should always assume its natural angle, which is usually about 120°.

Practice inspections and know what to look for, avoid battening down, avoid exposing your wire rope sling to abrasive forces and chemicals, and you can avoid common wire rope sling damage.

Want more wire rope? Check out our pages on types of wire rope construction and wire rope grades.

——————————————————————————————————————————————

The Hercules Group of Companies encompasses a wide portfolio of products and services across 7 diverse companies.