Product Spotlight | Crosby Forged Sorting Hooks

Product Spotlight: Crosby Forged Sorting Hooks

Today, the Hercules SLR product spotlight is on Crosby forged sorting hooks. While sorting hooks may not be a piece of rigging equipment the everyday rigger reaches for every day, handy when put to use in their intended capacity.

Sorting hooks are manufactured for use in sorting and laying out plates, pipes, cylindrical or tube shapes and other items that allow the full depth of the hook throat to be engaged. They are always used in multiple sling leg applications, in order to balance the load by engaging it on multiple ends.

Although many hooks used in overhead lifting are required to be equipped with a latch, sorting hooks are one of the few types of hooks designed not to use a latch as it would limit the practical use of the hook when lifting plates and cylindrical loads where full throat engagement of the hook is required.

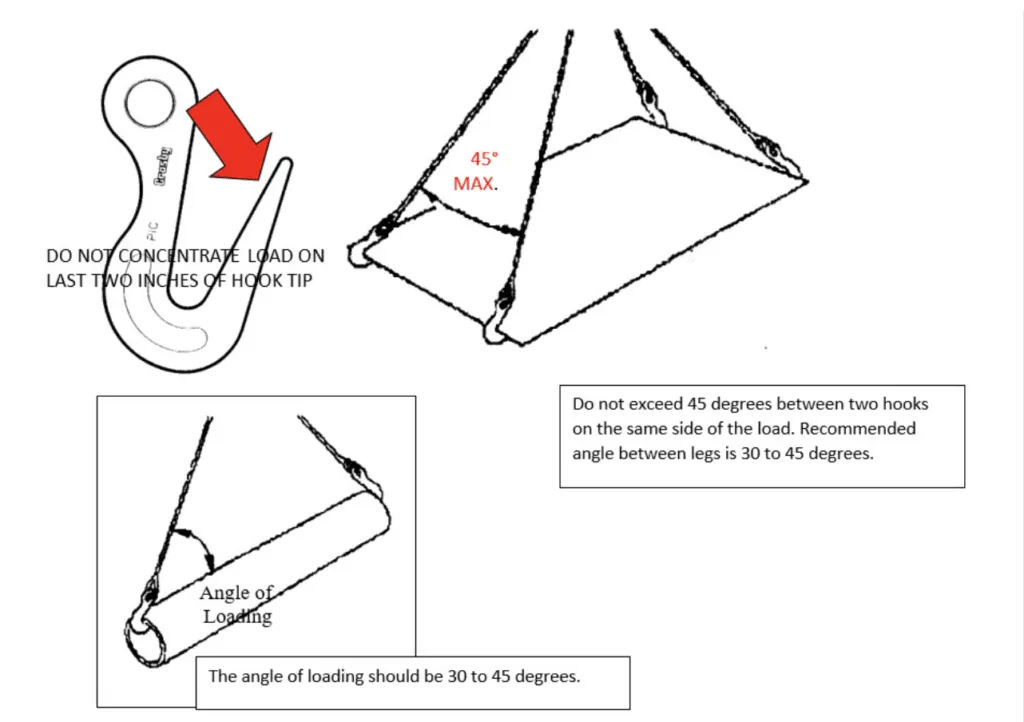

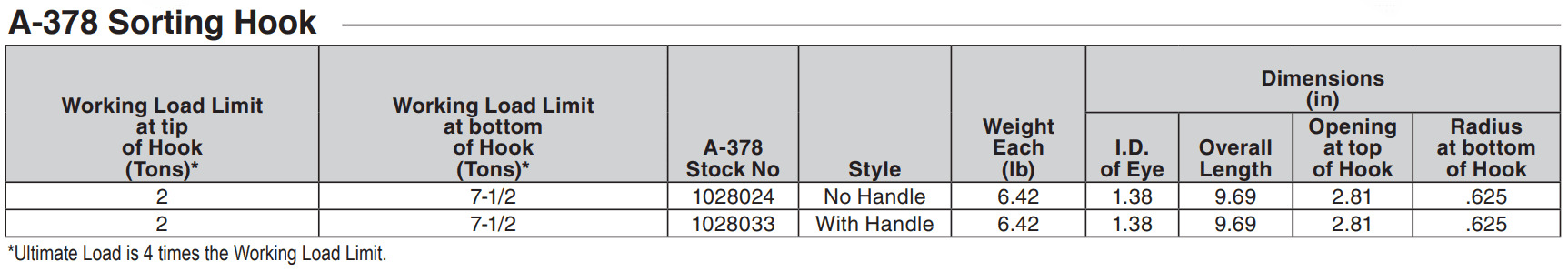

Sorting hooks should be used at a 30° to 45° angle to get full engagement. Since the equipment functionally relies on its long throat being fully engaged, if you fail to do this, it will result in a significant reduction to the working load limit (WLL) of the hook. With this being said, you never want to concentrate your load on the last two inches of the hook tip, as this too would mean the full throat of the hook would not be properly engaged – and that section of the equipment is not made to support significate weight as it tapers off to being much thinner then the weight baring sections of the hook.

Sorting Hook 1Sorting Hook 2Crosby Forged Sorting Hooks are made of forged alloy steel that’s both quenched and tempered.

This heat treatment provides consistent temperature control and results in superior material properties.

*But what in the world is quenching and tempering? The process of quenching or “quench hardening” involves heating the material and then rapidly cooling it to set the components into place as quickly as possible. Tempering is achieved by heating the quenched material below the critical point for a set period of time, then allowing it to cool in still air.

10 Tips From Crosby to Keep In Mind When Using Sorting Hooks

- The sorting and laying out process includes moving these materials at a height close to the ground with the load and load connections visually observable by the crane operator throughout the entire load handling activity.

- The hooks must be attached in a manner that will maintain a level, balanced and stable condition throughout the entire process.

- If the load exhibits obvious bending, the lift must then be immediately stopped for analysis and evaluation to ensure safety.

- During the load handling activity, the slings with hooks at the load connections must remain under tension at all times to prevent any of the hooks from disengaging.

- Never concentrate loading on the last 2 inches of the hook tip.

- Never exceed 45 degrees “included angle” between two sling legs that are on the same side of the load. Exceeding 45 degrees may result in the slings slipping along the load surface.

- The recommended angle of loading when using sorting hooks is 30 to 45 degrees. These lower angles, although typically discouraged for most rigging applications, allows the load to more easily obtain full hook throat engagement. When the angle of loading is greater than 45 degrees, tip loading and failure to obtain full hook throat engagement is very much a concern.

- Sorting hooks are for straight in-line loading only. Sideloading applications are not allowed.

- Calculate the sling tension and know the loading in all connection points to ensure all rigging gear is sized appropriately.

- Never exceed the working load limit as stated on the sling identification tag. Remember, sorting hooks are used in multiples, such as two-, three-, or four-leg wire rope sling assemblies. All slings require proper identification including the capacity of the sling assembly.

Bonus Tip!

Sorting hooks are known as many things, such as lay out hooks, shake out hooks or pelican hooks. Though, if you refer to them as pelican hooks, be sure the person you’re speaking with truly knows what you mean because there is actually a different type of hook used in nautical and marine applications that’s really called a pelican hook. The real pelican hook is meant for securing ship anchors, life raft canisters or cargo gear and they are not rated to perform overhead lifts.

Pssstt…If you’re looking for an actual pelican hook, head on over to Hercules SLR’s sister company, Spartan Marine! Spartan Marine is your source for high-quality marine products and services, offering a wide range of solutions to those with industrial, commercial and recreational marine interests.

Crosby is one of the most recognizable names in the rigging industry and has been for over 100 years. Crosby makes over 2,000 rigging and lifting products to meet all your hoisting needs, and Hercules SLR is proud to be an Authorized Crosby Distributor and a Certified Crosby Repair Center.

Why shop around? When you buy Crosby rigging equipment from Hercules SLR, you don’t just get a shackle or an eye bolt—You get unparalleled asset management service (did we mention it’s free?), qualified inspection technicians for service & preventive maintenance and peace-of-mind knowing your equipment is safe to lift, hoist or move.

See your Crosby gear from purchase, all the way to service with Hercules SLR’s extensive product selection, inspection & service team, asset management, testing and more.

——————————————————————————————————————————————

The Hercules Group of Companies encompasses a wide portfolio of products and services across 7 diverse companies.