Crosby Shackles Used on SpaceX

Crosby Shackles Used on SpaceX

This week The Crosby Group shared on their Linkedin that Crosby shackles were spotted being used on SpaceX’s most recent starship, the SN20.

They shared a photo of the starship and wrote: “Great to see our shackles in use on the starship SN20 SpaceX project in this recent post by spacex_starship on Instagram.

The Starship prototype, known as SN20, left its production facility near the South Texas village of Boca Chica to arrive at the launch pad last week.”

Did you know that even the rocket science industry depends on rigging hardware and technology in order to successfully see their work come to life?  Even a record-breaking company like SpaceX relies on the tried and true technology of rigging.

Even a record-breaking company like SpaceX relies on the tried and true technology of rigging.

In December of 2019 we shared the blog, Rigging in Space: SpaceX Uses Crosby, where we shared how Crosby wide body shackles were used on an early SpaceX Starship prototype, MK1. And now, three years later SpaceX is still notably using Crosby Shackles in the construction of their Starships. There’s something to be said that even after 3 years of development, this advanced rocket and spacecraft manufacturer is still choosing Crosby shackles.

Crosby Shackles

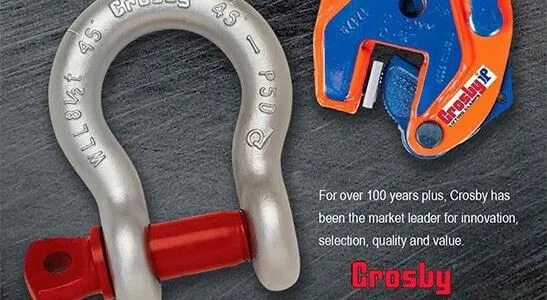

Crosby is one of the most recognizable names in the rigging industry, and has been for over 100 years. Crosby makes over 2,000 rigging and lifting products to meet all your hoisting needs, and Hercules SLR is proud to be an Authorized Crosby Distributor and a Certified Crosby Repair Center.

When you buy Crosby, you’re getting some attributes that are guaranteed when you buy their rigging and lifting equipment. The attributes that make Crosby shackles stand out from the rest include:

- Design – Crosby carbon shackles have the highest design factor (6 to 1) in the industry. Crosby purchases only special bar forging quality steel with cleanliness and guaranteed hardenability. All material chemistry is independently verified prior to manufacturing to assure that strength, ductility and fatigue properties are met.

- Closed Forged – Each shackle is closed die forged which allows for an increased cross-section that, when coupled with quenched and tempering, enhances strength and ductility. Close tolerance holes and concentric pins with good surface finishes are provided by Crosby and are proven to provide improved fatigue life in actual use. Crosby shackles are fatigue rated as well as load rated.

- Quenched and Tempered – All Crosby shackle bows and pins are quenched and tempered, which enhances their performance under cold temperatures and adverse field conditions. Crosby’s Quenched and Tempered shackles provide the tensile strength, ductility, impact and fatigue properties that are essential if they are to perform time after time in adverse conditions. These properties assure that the inspection criteria set forth by ANSI will effectively monitor the ability of the shackles to continue in service.

- Identification and Application Information – Crosby forges “Crosby” or “CG”, the Working Load Limit, and the Product Identification Code (PIC) into each bow and “Crosby” or “CG”, and the Product Identification Code (PIC) into each pin of its full line of screw pin, round pin, and bolt type

anchor and chain shackles.

Crosby creates a variety of different shackles ranging in size, type, class, capacity and more to exceed the toughest demands of any industry, including land-based and offshore energy, construction and infrastructure, cargo handling and towing, marine, mining, and transportation.

SpaceX Starship SN20

SpaceX has rolled out it’s newest version of the Starship, the SN20. On Aug 5, 2021 Starship SN20 left its production facility near the South Texas village of Boca Chicaand and joined it’s Super Heavy first-stage booster on the launch pad. The following day the SpaceX Starship was fully stacked in preparation for an orbital test flight. Once SpaceX Starship SN20 was fully stacked, it became the world’s tallest rocket.

The stacked spacecraft measures 395 feet tall standing alone, and 475 feet tall with it’s launch stand. This is taller than any other rocket including NASA’s famous Saturn V moon rocket, which was 363 feet tall.

SpaceX has tested many Starship prototypes in flight, but the SN20 will be the first attempt at putting a Starship into orbit. SpaceX’s orbital flight plan submitted to the FAA states that the Super Heavy Booster 4 will come down into the Gulf of Mexio roughly 20 miles offshore and then the Starship will boost itself into orbit to circle the Earth once and return over the Pacific Ocean near the Hawaiian Island of Kauai. This is set to take approximately 90 minutes.

However, the date of when this exhibition will take place is still unknown at this time. The Starship will first have to undergo numerous  technical examinations as well as a environmental review before gaining clearance to leave it’s launch pad.

technical examinations as well as a environmental review before gaining clearance to leave it’s launch pad.

On Twitter, Elon Musk also wrote that Starship and its Super Heavy booster will need at least “4 significant items” before it will be ready to fly. Those items are final heat shield tiles for the Starship, thermal protection for Super Heavy’s engines, more ground system propellant storage tanks, and a quick-disconnect arm for the Starship.

We don’t know when SpaceX newest Starship will hit orbit —But something we can always be sure about is Crosby. The Crosby brand has been trusted for more than 130 years as the world’s leading manufacturer for rigging, lifting, and material handling applications.

Crosby delivers the industry’s most comprehensive portfolio of products, engineered to exceed the toughest demands. Hercules SLR is proud to be an Authorized Crosby Distributor and a Certified Crosby Repair Center. See your Crosby gear from purchase, all the way to service with Hercules SLR’s extensive product selection, inspection & service team, asset management, testing and more.

——————————————————————————————————————————————

The Hercules Group of Companies encompasses a wide portfolio of products and services across 7 diverse companies.