Exploring the World of Load Cells

Exploring the World of Load Cells

Rigging, the art of lifting and moving heavy loads with precision, relies on a combination of skill, expertise, and technology. One crucial technological component that plays a pivotal role in ensuring safety and accuracy is the load cell.

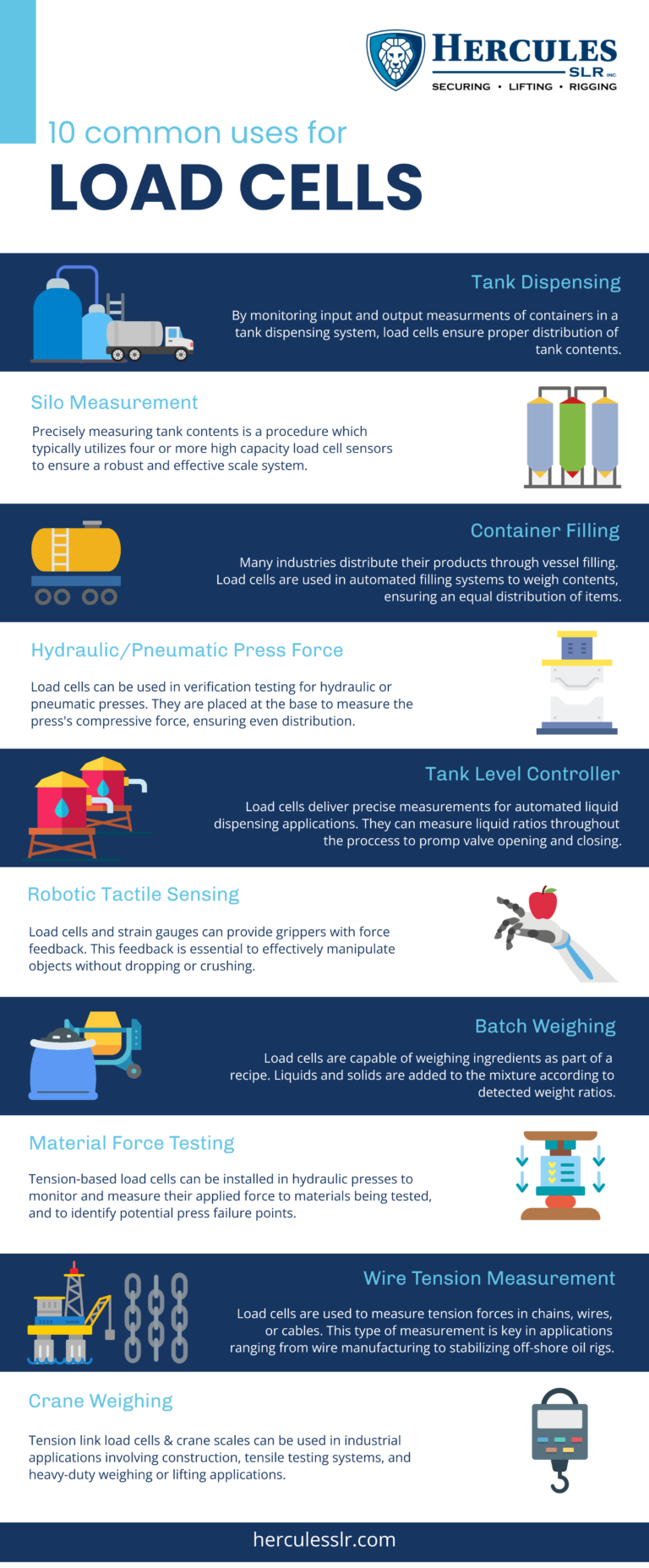

Load cells are precision force-measuring instruments. They offer a relatively low-cost, durable, and easy-to-install solution to almost any load measurement need. Load cells have been providing quality measurements in aerospace, agriculture, medicine, industrial weighing, and many other applications for decades. Ongoing advancements in load cell technology have further broadened their use.

This article explains the different types of load cells that exist, their basic function, and which types are best for various general uses.

In this blog post, we will dig a little deeper into the world of load cells, understanding their significance in rigging applications, their types, and the evolving technology that makes them indispensable in modern rigging scenarios.

Understanding Load Cells:

Load cells are transducers that convert force or load into an electrical signal. In the context of rigging, load cells are essential instruments used to measure the force applied to a load during lifting or tensioning operations. By providing real-time data on the load, they enable riggers to make informed decisions, ensuring the safety of both personnel and equipment.

Types of Load Cells:

Load cells come in various types, each designed to cater to specific rigging requirements. The four main types are:

1.Strain Gauge Load Cells:

- These are the most common types of load cells and operate on the principle of strain gauges.

- Strain gauges are bonded to a flexible material that deforms under load, causing a change in electrical resistance.

- This change is measured and converted into a load value.

2. Piezoelectric Load Cells:

- Piezoelectric load cells use crystals that generate an electrical charge when subjected to mechanical stress.

- The generated charge is proportional to the applied force, allowing for accurate load measurement.

- They are known for their high sensitivity and fast response times.

3. Hydraulic Load Cells:

- These load cells use hydraulic fluid to measure force.

- The force applied to the load causes a change in pressure in the hydraulic fluid, which is then measured and converted into an electrical signal.

4. Capacitive Load Cells:

- Capacitive load cells rely on changes in capacitance to measure force.

- As the load is applied, the distance between capacitor plates changes, leading to a change in capacitance.

- This change is then converted into an electrical signal for load measurement.

The Role of Load Cells in Rigging:

- Safety:

- Load cells play a crucial role in ensuring the safety of lifting operations. By providing real-time load data, riggers can prevent overloading, a leading cause of accidents in rigging scenarios.

- The ability to monitor loads continuously allows for quick response in the event of unexpected changes, minimizing the risk of equipment failure.

2. Precision and Accuracy:

- Rigging operations demand precision, especially in industries such as construction, offshore drilling, and entertainment.

- Load cells enable riggers to achieve the desired level of accuracy in load measurement, ensuring that loads are lifted and moved with the required precision.

3. Data Logging and Analysis:

- Modern load cells are equipped with advanced features such as data logging and wireless communication.

- Data logging allows riggers to record load data over time, facilitating analysis and optimization of lifting processes.

- Wireless communication enables real-time monitoring and control, enhancing overall operational efficiency.

4. Versatility:

- Load cells are versatile tools that can be adapted to various rigging applications.

- They come in different shapes and sizes, making them suitable for diverse load-bearing scenarios, from small-scale lifts to heavy industrial operations.

5. Cost Efficiency:

- While the initial investment in load cells may seem significant, their long-term benefits in terms of safety, efficiency, and equipment lifespan often outweigh the costs.

- The ability to prevent accidents and optimize lifting processes can result in substantial cost savings over time.

The Evolving Technology:

As technology continues to advance, so do load cells. Some recent developments in load cell technology include:

Wireless Connectivity:

- Many modern load cells come equipped with wireless connectivity options, allowing for remote monitoring and control.

- This feature is especially valuable in large-scale rigging operations where real-time data access is essential.

Integrated Sensors and Electronics:

- Load cells are now designed with integrated sensors and electronics, eliminating the need for external signal conditioning devices.

- This integration enhances reliability and reduces the complexity of the rigging system.

Smart Load Cells:

- Smart load cells are equipped with embedded processors and sensors that enable them to perform self-diagnosis.

- They can detect issues such as sensor malfunctions or overloads, providing an additional layer of safety.

In Summary

Load cells are the unsung heroes of the rigging world, silently working behind the scenes to ensure that lifting operations are carried out safely and efficiently. Their ability to provide real-time load data, precision, and versatility makes them indispensable in a wide range of industries. As technology continues to evolve, load cells will likely play an even more significant role in shaping the future of rigging, contributing to safer and more efficient lifting operations.

——————————————————————————————————————————————

The Hercules Group of Companies encompasses a wide portfolio of products and services across 7 diverse companies.