NDT: Introduction to Liquid Penetrant Testing (PT)

Liquid Penetrant Testing is one of the most popular Nondestructive Testing (NDT) methods in the industry. Nondestructive testing (NDT) is the process of inspecting, testing, or evaluating materials, components or assemblies for discontinuities without destroying the serviceability of the part or system. So, in other words, it allows for inspection of a part or material without having to take it out of service!

Today, non-destructive tests are used in industries like Aviation, Space, Ships, Bridges, Refineries Mining, Nuclear, Manufacturing, Fabrication and in-service inspections. Ever drive a car? Chances are, you use something in your daily life that’s been NDT inspected at some point in time!

In today’s blog, we’re going to touch on the basics of Liquid Penetrant Testing so you can better decide if this form of inspection would be suitable for your application! At Hercules SLR our experts perform Liquid Penetrant Testing as well as Magnetic Particle Inspection, and Ultrasonic Testing.

Liquid Penetrant Testing Basics

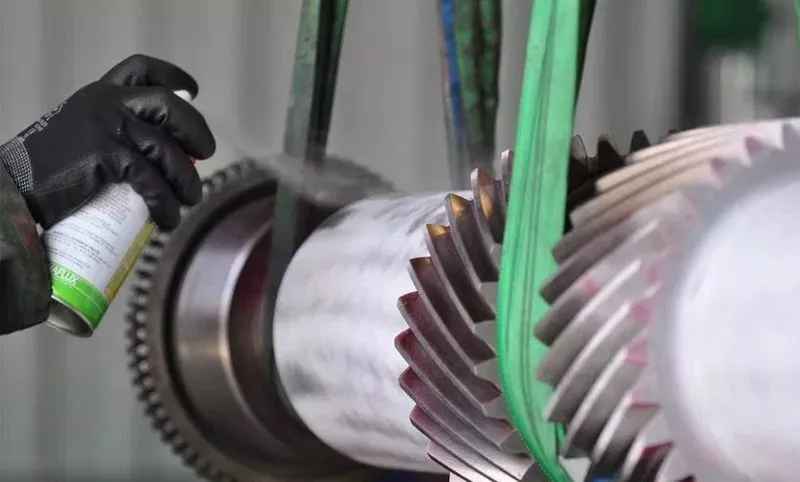

Liquid penetrant testing is a method of NDT that uses fluid to reveal surface flaws on parts and equipment without compromising the integrity of the item. Liquid penetrant tests can be conducted using solvent removable penetrants, water washable penetrants or post-emulsifiable penetrants. These low viscosity fluids are highly sensitive and seep into even the smallest surface defects such as cracks or porosity, and once the access fluid is removed, the liquid trapped in the surface will flow back out, creating a visual indication of the flaws.

It is usually a six-stage process:

- Surface cleaning

- Application of a penetrant liquid

- Removal of excess penetrant

- Application of developer

- Inspection of test surface

- Post-inspection cleaning

There are three major groups of penetrant process:

1. Water-soluble

2. Post-emulsifiable with water rinsing

3. Solvent removable, the difference being in the method used to remove the excess penetrant.

In each of these three groups the penetrant solution can contain a dye to make the indication visible under white light, or a fluorescent material which fluoresces under suitable ultraviolet (UV-A) light. The choice of technique for any specific application is based on: the surface finish of the specimen, the compatibility of the materials with the specimen, the sensitivity required, the size, shape and accessibility of the area to be inspected and the ultimate use of the component.

Liquid penetrant testing is perfect for large volumes of parts or materials, including those with complex geometric shapes, as they can be inspected rapidly at a lower cost than other examination methods. Liquid penetrant testing has very few material limitations, i.e. metallic and nonmetallic, magnetic and nonmagnetic, and conductive and non-conductive materials may be inspected. However, this examination method does not work well on porous materials.

The PROS of Liquid Penetrant Testing

The PROS of choosing liquid penetrant testing are:

1. Works on complicated geometric shapes

2. Materials necessary for inspection are compact

3. Sensitive to small surface interruptions

4. Few material limitations such as—works on non-metallic, metallic, non-magnetic, magnetic, non-conductive and conductive materials

5. Liquid penetrant testing materials are individually very cost-effective

6. Visual, real-world results very quickly!

The CONS of Liquid Penetrant Testing

The CONS of choosing liquid penetrant testing are:

1. Requires extensive pre-cleaning as surface contaminants can mask defects

2. Sensitive to surface-breaking defects only

3. Direct connection to the surface under test is necessary

4. Works on relatively non-porous surface materials only

5. No depth sizing

6. Post-cleaning also necessary

Save downtime by testing for the imperfections in your parts that you may not be able to see in routine inspections. Contact Hercules SLR’s liquid penetrant testing experts for more information!

Hercules SLR is part of the Hercules Group of Companies which offers a unique portfolio of businesses nationally with locations from coast to coast. Our companies provide an extensive coverage of products and services that support the success of a wide range of business sectors across Canada including the energy, oil & gas, manufacturing, construction, aerospace, infrastructure, utilities, oil and gas, mining and marine industries.

Hercules Group of Companies is comprised of: Hercules SLR, Hercules Machining & Millwright Services, Spartan Industrial Marine, Stellar Industrial Sales and Wire Rope Atlantic.

We have the ability to provide any solution your business or project will need. Call us today for more information. 1-877-461-4876. Don’t forget to follow us on Facebook, Twitter and LinkedIn.

——————————————————————————————————————————————

The Hercules Group of Companies encompasses a wide portfolio of products and services across 7 diverse companies.