Engineering Marvels: Rigging the Great Wall

Engineering Marvels: Rigging the Great Wall

In the annals of human history, certain architectural wonders stand as testaments to the ingenuity and perseverance of ancient civilizations. The construction of iconic structures such as the Great Wall of China, the Colosseum in Rome, and the Pyramids of Egypt not only symbolizes the grandeur of their respective cultures but also unveils the remarkable rigging techniques that made these feats possible. In this ‘Engineering Marvels” series of blog posts, we embark on a journey through time to unravel the rigging secrets behind these historical projects, exploring the challenges faced by ancient engineers and the innovative solutions that shaped these enduring marvels.

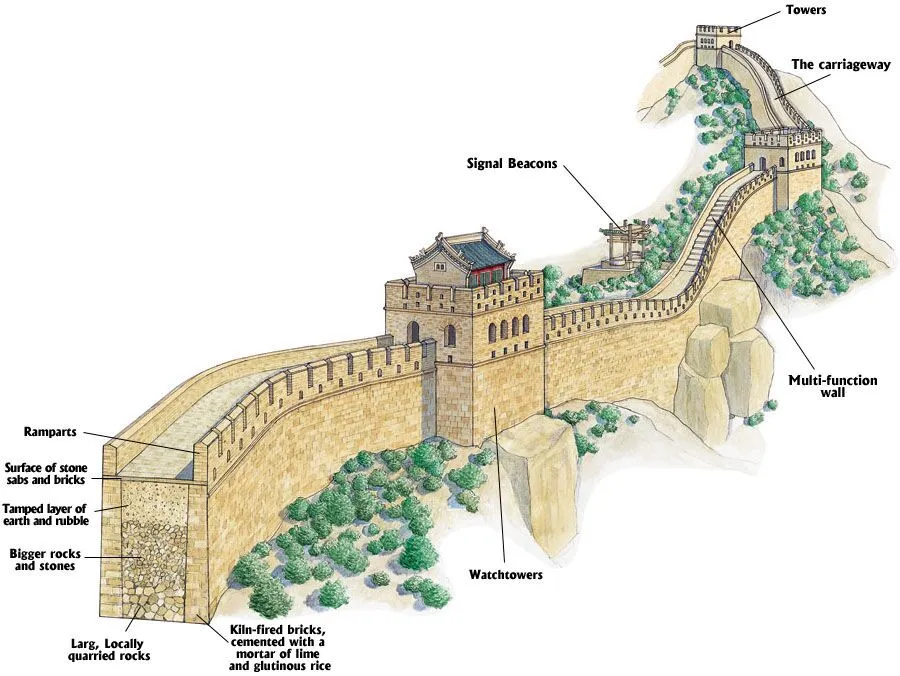

The Great Wall of China, hailed as one of the world’s most remarkable wonders, captivates the imagination, inviting intrigue into its origins and the enduring myth of its visibility from the moon. Spanning a construction timeline of 2300 years, encompassing an impressive length of 21,196.18 kilometers, and utilizing an astounding 100,000,000 tonnes of material, the (Chang Cheng), known as the “Long Wall” in Chinese, stands as an extraordinary feat in defensive architecture. Crafted with a singular strategic objective, it serves as a formidable guardian, dedicated to safeguarding China and preserving its rich cultural heritage.

Beyond its historical significance as a defensive structure, the construction of the Great Wall is a fascinating study in ancient engineering and rigging. In this exploration, we delve into the intricate rigging aspects of the Great Wall, unraveling the technical complexities and revealing compelling facts that showcase the scale of this historical project.

I. Setting the Stage: A Monumental Defense Project

The construction of the Great Wall was initiated in the 7th century BC and continued for centuries, spanning various dynasties. Its primary purpose was to protect Chinese states and empires from invading forces, a mission that required a colossal effort in terms of both manpower and engineering prowess.

Rigging played a pivotal role in the transportation and placement of the massive stones and bricks that form the backbone of the Great Wall. Technical ingenuity was required to overcome the diverse and challenging topography that the wall traversed, including mountains, valleys, and steep ridges.

II. Transportation Challenges: Rigging Across Rugged Terrain

The Great Wall’s construction involved the transportation of massive stones and bricks from quarries to the construction sites, a process that demanded innovative rigging solutions. To navigate the rugged terrain, ancient Chinese engineers employed a combination of manpower and rudimentary rigging systems.

Interesting Fact #1: Builders utilized wooden sledges and cranes to transport and lift the colossal stones. Sledges were equipped with wooden rollers to reduce friction, allowing for smoother transportation across uneven surfaces.

III. Human-Powered Rigging: A Collaborative Effort

One of the remarkable aspects of the Great Wall’s construction was the collaborative effort of the workforce who worked together to transport and position the heavy stones using human-powered rigging systems.

Originally, soldiers were picked for the construction, but soon the effort was expanded to include skilled laborers, farm workers, teachers, musicians and even criminals. For them, this was an unfortunate destiny; many of them spent their whole lives building the Great Wall and anyone who had a say about the operation was killed. Many lives were lost during the process, and some of the bodies were buried under the wall.

Technical Aspect: Pulley systems were employed to multiply the force applied to lifting mechanisms, enabling the controlled ascent of stones to elevated sections of the wall.

Interesting Fact #2: Bamboo, known for its strength and flexibility, was used in the construction of ropes for rigging purposes. Bamboo ropes were not only durable but also resistant to the harsh weather conditions prevalent during construction.

IV. Tackling Height and Precision: Rigging for Vertical Growth

The vertical nature of the Great Wall presented unique challenges in terms of lifting stones to considerable heights. To overcome this, ancient Chinese engineers implemented various rigging techniques, including the use of cranes and treadwheel devices.

Technical Aspect: Treadwheel cranes featured a large, vertically mounted wheel that was turned by human or animal power. Ropes were wound around the wheel, allowing for the controlled lifting of heavy materials.

Interesting Fact #3: The treadwheel cranes used in the construction of the Great Wall were operated by teams of laborers who walked inside the wheels, providing continuous power for lifting operations.

V. Rigging and Adaptation: The Wall’s Evolution Over Centuries

As the construction of the Great Wall progressed through different dynasties, so did the evolution of rigging techniques. Builders adapted their methods to overcome new challenges and incorporate technological advancements.

Technical Aspect: Improvements in pulley systems and the introduction of cam pulleys enhanced the efficiency of rigging operations. Cam pulleys featured grooved wheels and rotating axles, reducing friction and wear on ropes.

Interesting Fact #4: The Great Wall is not a single continuous structure but rather a series of walls and fortifications built by different dynasties. This diverse construction history reflects the adaptive nature of rigging methods employed over the centuries.

VI. Beyond Defense: The Symbolic Legacy of the Great Wall

The Great Wall of China, while initially constructed for defense, transcends its practical purpose to become a symbol of China’s rich history and cultural heritage. Rigging played a pivotal role in turning the vision of a defensive barrier into a tangible reality, shaping the landscapes and narratives of ancient China.

Technical Aspect: Rigging systems were crucial in the construction of watchtowers and beacon towers along the wall, allowing for strategic positioning and effective communication.

Interesting Fact #5: Contrary to the common belief that the Great Wall is visible from space, it is challenging to discern with the naked eye from low Earth orbit. This myth, however, underscores the scale and impact of this engineering marvel.

The Great Wall of China stands as an enduring testament to the collaborative efforts, technical ingenuity, and adaptive engineering of ancient China. Rigging played a central role in overcoming the geographical challenges and logistical complexities inherent in such a monumental construction project. From the transportation of massive stones across rugged landscapes to the controlled lifting of materials to towering heights, the rigging of the Great Wall showcases the remarkable capabilities of ancient Chinese engineers. As we marvel at the vastness and historical significance of the Great Wall, let us not forget the unsung heroes of rigging whose innovations shaped one of the world’s most iconic structures.

——————————————————————————————————————————————

The Hercules Group of Companies encompasses a wide portfolio of products and services across 7 diverse companies.