Safe Rigging Practices

Safe Rigging Practices

Safe rigging practices are essential to get the job done and get home in one piece. Today, we spoke to our rigging experts from our Brampton, Ontario branch—some of their clients include IMAX, Siemens, GM and Bombardier. Read on to learn more about safe rigging practices to use when rigging with wire rope slings.

What is safe rigging—or even rigging in general?

Rigging, or safe rigging is simply the movement of a mass using mechanical application, like slings and/or lifting equipment. The term ‘rigging’ also includes figuring out what lifting appliances and slings should be used and fitted to control the load (never vice versa!), and where the load should be moved to.

Safe Rigging Practices: 4 steps

- Identify the load and find out its weight;

- Find best sling for the load and select lifting gear;

- Ensure the route your load will travel is clear and there are no hazards present;

- Prepare the area where you load will land, make sure there are no obstructions.

Safe Rigging Practices: lifting with wire rope slings

Okay, so you’ve decided wire rope slings are the best sling to lift your load—but wait! Before lifting with wire rope slings, determine these 3 things:

- Know or determine the weight of the load;

- Decide the sling arrangement—consider load control, type and means of attachment;

- Sling length—consider available headroom, leg angle.

When executing your lift with a wire rope sling, be sure to protect the load and sling from damage at sharp corners—padding the corners is recommended. Be sure to block as needed, examine your sling before each lift and use safe operating practices. This will also help prevent common wire rope sling damage.

While operating, make sure the following happens:

- Sling is centered in bowl of hook;

- Each leg supports part of the load so it’s under control;

- Sling(s) are long enough that rated load angle is accurate;

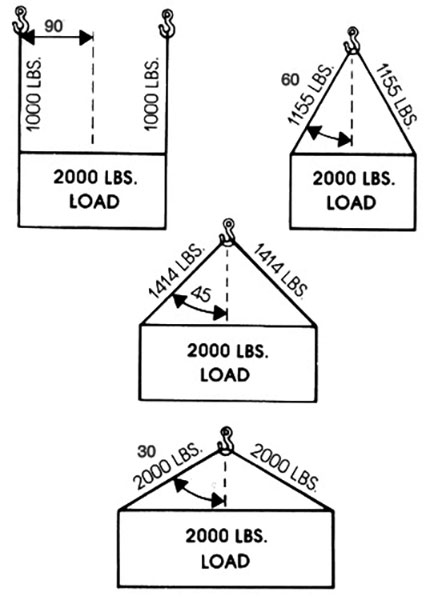

- If using multiple slings for different, specific angles, don’t load each leg with more than is permitted;

- Stay alert for potential snags;

- Balance basket hitches in choker hitches to prevent slip;

- The load doesn’t exceed the rated load of sling or components and load is within rated load of sling (avoid shock-loading);

- Stay clear of rigging equipment and especially a suspended load;

- The load won’t collapse or change shape/form when in contact with bumps or jerk-movements;

- After use, inspect and properly store the sling.

Multi-Leg Wire Rope Slings

If the load needs a multi-leg sling, do not exceed the SWL stamped on the ring—the SWL (safe working load) will always be slated for sling legs at 90°.

Safe Rigging Practices: slinging tubulars with wire rope slings

Tubular items include scaffold tubes, drilling tubulars, construction pipe work and other items like these. When rigging tubulars in a sling, consider the following:

- Only tubulars of the same diameter should be placed together;

- The amount of tubes should be placed so middle tubes are gripped and won’t slip out of the bundle;

- Tubulars should always be slug with two slings, each with a SWL at least equal to the gross weight of the load;

- Slings should be placed at an equal distance apart—around 25% from the loads’ end. Place sling legs 1/4 of the tube length from the ends of tubes;

- Use clamps or bulldog clips on the reeved wire to prevent loosening. Use a tie wrap on the sling’s reeved eye to prevent the sling from slipping over the bulldog;

- Attach a tag line to one sling when rigging excessively long, tubular bundles.

Remember�—it’s dangerous to bundle tube with steel angle, channels, etc. Small bore tube may lay loose in the gaps between differently shaped items of steel and could slide out when lifted. At height with the right amount of force, a tube can become a spear and result in fatal injuries.

Safe Rigging Practices: single-leg vertical hitch

Keep these tips in mind when using a single-leg vertical hitch:

- The total weight of the load is supported by a single leg;

- The SWL of the wire rope sling must exceed the load weight;

- Don’t use your hitch to lift loose materials, long loads (unless using a spreader beam with 2 single-legs—see below) or a load that can tip;

- Single-leg hitch won’t provide you with good control and is prone to tip.

Single-Leg Vertical Hitch: Spreader Beams

Use a certified spreader beam for good control to support loads that are long and/or hard-to-handle. They reduce the tendency for the load to slip or bend, and both single legs will support the load—if the load is evenly balanced, each side will carry half the load.

Safe Rigging Practices: double-up

Double Basket

- Make sure two hitches are placed carefully to ensure load is balanced;

- Ensure legs are kept apart enough to balance the load (don’t cause slippage);

- Never use a vertical angle bigger than 60°;

- Double basket hitches don’t have great load control, the capacity depends on the vertical angle formed in the basket.

Double Wrap Basket

A double wrap basket is a basket hitch that’s wrapped around the load. When using this method with wire rope slings, keep in mind:

- A single hitch doesn’t control load slippage;

- Adjust legs as load is applied, equalize load balance;

- Great for loose material handling and smooth loads due to it’s 360° wrap;

- For good load control, use two hitches when at a horizontal angle of 45° or smaller (depending on load weight).

Double Wrap Choker

A double wrap choker hitch is a choker hitch wrapped around the load—a single hitch won’t control load slippage. These are great for handling loose materials as it has a 360° wrap that can be achieved without battening down the eye—gain control by using two hitches at a horizontal angle of 45° or smaller.

Safe Rigging Practices: stabilizing & landing the load

Before you begin lifting your load, you should have a plan and prepared space for the load to land. The type of load will determine how riggers prepare but typically, most loads should be lowered onto timber battens. Slings will be easy to withdraw from the load, but remember—never land a load directly on the sling.

A good rigger will always asses unusual loads and try to estimate their center of gravity in order to stabilize it. It’s important to attach slings so the center of gravity is below or within the lift points. If you doubt the load’s stability at all, lift it very slowly. If it tilts, lower it (slowly) and re-sling the load so it’s stable.

——————————————————————————————————————————————

The Hercules Group of Companies encompasses a wide portfolio of products and services across 7 diverse companies.