Safety Gloves: An Important Part of Your PPE

Safety Gloves: An Important Part of Your PPE

What comes to mind when you think of the number one tool you use at work? For many people, the correct answer to this question is right in front of you—Your hands.

You may not consider it, but your hands do a lot throughout the day, and I bet your job would get a whole lot harder without them. But yet, when it comes to assembling your personal protective equipment (PPE), sometimes proper safety gloves don’t make the list. You, like many others, may not understand why protecting your hands is so important, or what type of glove is the right choice for you—Because it’s not just about wearing safety gloves, it’s about wearing the right safety gloves.

Protect your #1 tool, and read on to learn a bit more about why safety gloves are so important, and how to choose the right ones for your work conditions.

The Importance of Wearing Safety Gloves

Not only are your hands one of your most important tools, they are very complex tools that aren’t always easy to fix (as you can imagine, spare parts are hard to track down). If a severe hand injury accrues, you may have to deal with effects like loss of motion, dexterity, and grip for the rest of your life.

But the good news is – Many of these injuries can be prevented by wearing the right safety gloves. Safety glove technology has progressed to include features like being cut-resistant, heat-resistant, anti-impact, anti-vibration, and so much more! You shouldn’t have an issue tracking down a glove that will protect you from any hazards present in your workplace.

What Hazards do Safety Gloves Protect Against?

Chemical and Biohazards – When handling chemicals or biohazards, it can only take one touch to cause a chemical burn or infection. Because of this, you need a glove that forms a complete barrier around your hands. Typical glove materials for chemical protection are latex, nitrile, neoprene, polyvinylchloride, or other polymers – Like the Chemstop™ – Premium Quality PVC Coated Gloves. For chemical mixtures or jobs where multiple hazards are present, it may be necessary to wear gloves that have the highest chemical resistance or in some cases wearing a combination of different types of gloves. Employers should always refer to the chemical’s Material Safety Data Sheet (MSDS) for selecting the correct glove materials. Need to brush up on your WHMIS knowledge? Check out our WHMIS 2015 with GHS course!

Cuts, Punctures and Abrasion Hazards – It’s fairly common for these types of hazards to be present in the workplace. For these hazards, gloves need to be able to protect your hands from things like abrasive surfaces, wood and metal splinters and injuries associated with cut or scrapes while still providing high levels of dexterity and tactile sensitivity. Typical materials for cut and puncture protection are leather, canvas, cotton, cotton blends or other synthetic materials. Often times additional protection is added by applying various coatings to sections of the glove or by lining the gloves with impact or vibration-dampening gels or pads.

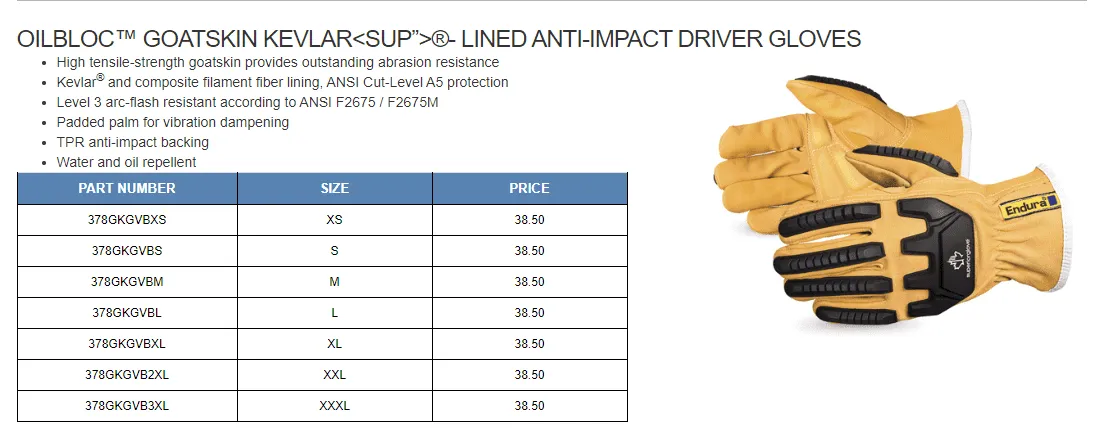

Impact Injuries – If you’re performing tasks like swinging a hammer or lifting heavy objects then you need gloves that protect you from impact injuries. Any job where your hands might be crushed or hit by tools, equipment, or supplies requires reliable, impact-resistant work gloves. Impact-resistant gloves feature a padded outer shell strategically placed to the areas on your hands where impacts are most likely to occur. Gloves like Oilbloc™ Goatskin Kevlar “SUP”® Lined Anti-Impact Driver Gloves allow some of the force of the impact to be absorbed and spread out over a larger surface.

Heat and Arc hazards – These hazards are present in many fields such as welding, glass manufacturing, petrochemical plants, oil fields, and the natural gas industries. Safety gloves that are specifically made to protect your hands against these hazards create a barrier that blocks the heat from reaching your skin. Depending on the temperature, type of heat (e.g. dry, moist, thermal, ambient), and other work factors, a variety of materials are used such as terry cloth or neoprene.

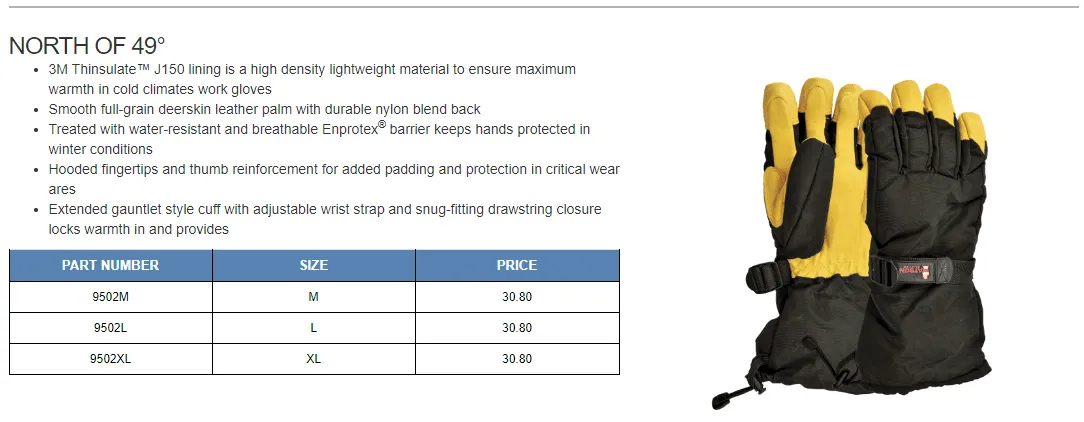

Severe Weather and Extreme Temperatures – If you’re working in a cold outdoor environment or even a cold-storage facility, you need a thermal barrier on your hands to protect them from damage and to maintain your body heat. Don’t be fooled, protecting yourself from extreme cold is just as important as protecting yourself from extreme heat. Cold temperatures can cause temporary or permanent damage to the skin and muscle tissue – The colder it is, the more protection you need. Gloves made to protect your hands from cold temperatures are often made from materials like PVC, nitrile, animal hide, or Thinsulate™ – as used in the North of 49° gloves.

Persistent Vibrations – Persistent vibration can irritate nerves and nerve endings, damage blood vessels, cause long-term joint and muscle pain, and, in extreme cases, even lead to permanent nerve damage such as neuropathy. You may think you only need gloves that help absorb vibrations when using tools that create a dramatic vibrations such as chainsaws or jackhammers, but in reality, even lower level of vibrations found in tools like sanders or grinders should be protected against because you’re more likely to use these tools for an extended period of time, not noticing the damage being done.

How to Choose the Right Type of Safety Glove

As we mentioned before, keeping your hands safe isn’t just about throwing on any glove you can find – It’s important you’re using the right ones. No single type of glove will provide protection against all safety hazards. You should always check with your jurisdiction to see if there are any regulations around hand protection, but in general, employers are tasked with performing a hazard assessment in order to choose the correct gloves to provide to their employees. But remember, your workplace safety should always be something you take into your own hands. If you feel you haven’t been provided with the correct gloves for your job – speak up!

Based on tips from The Canadian Centre for Occupational Health and Safety (CCOHS), these steps can help you perform your own hazard assessment and consider whether you’re using the correct gloves for your job.

- Take time to think through your work tasks and environments so you have an accurate description in your mind (or on paper if that helps you!) of your day to day work.

- Identify all hazards that you come in contact with that may require hand protection. This should include any chemicals you come in contact with as well as physical hazards such as abrasions, tearing, puncturing, fire, temperature, and/or biological hazards.

- Determine the amount of flexibility and touch sensitivity you need to safely and effectively complete your tasks. This will affect your choice in thickness of glove material as well as if you may need a textured glove made to aid in grip.

- Take into considerating the type of contact you’re making with the hazards you’ve identified (e.g. occasional contact, splashing, or continuous immersion). This will affect your choice in an appropriate length of the glove, as well as the type and thickness of glove material, and whether you need lined or unlined gloves.

- Take into account any hazards that may be caused by the gloves themselves keeping in mind your other PPE. For example, heat stress, reduced dexterity, rip or tactile functions, poor comfort or contributing to skin conditions. It’s just as important to have a well-fitted, comfortable, and easy to wear pair of gloves. Gloves won’t protect anything if you’re never wearing them because they hurt your hands or make your job harder.

- Consider any decontamination procedures that need to be followed. Will the gloves need to be disposed of or cleaned after use? If they need to be cleaned, consider the cleaning method, how often they can be cleaned, and any special procedures required for disposing of the “decontamination wash waste”.

- Ensure you’ve been given the necessary education and training required which includes: what are the hazards of skin contact with the chemical/materials being used, what are the limitations of the gloves, what could happen and what to do if the gloves fail and when to dispose of or to decontaminate gloves.

Working through this list should give you an idea of what you’re looking for in a glove – working from there you can connect with manufacturers to ensure you’re purchasing a glove that fits your perfect criteria. And remember, it’s not just about the safety features – make sure you’re choosing a glove that’s comfortable, so you’re never drawn to leave them on the table – Even once.

Hercules SLR carries a wide variety of protective gloves and equipment to keep your hands safe no matter the task. Choose from a wide selection of gloves along with rubber gloves, hand guards, finger guards, and more. You will even find glove dispensers to keep items organized. Whatever work you do, Hercules SLR has the hand protection products your job requires.

——————————————————————————————————————————————

The Hercules Group of Companies encompasses a wide portfolio of products and services across 7 diverse companies.