Hoist Service

Hercules SLR Lever Hoist Service: Inspection, Test, Maintenance, And Certification

Hoist inspection: According to ASME standard B30.16, manual, electric, and air hoists need to be inspected by a trained professional at least once a year.

The consequences of incorrect maintenance and inspections can be life or death. Not to mention the immense financial impact an accident can have on a business.

The hoist safety experts at Hercules SLR can thoroughly inspect, test, and certify lifting hoists. Bring them to one of our shops across the country or have our trained service professionals come to you.

Our inspectors check over 25 inspection points on every hoist, ensuring they undergo a rigorous and thorough examination prior to designating them as “safe”.

Contact Canada’s hoist safety experts at Hercules SLR today.

Hoist Inspection, Repair & Certification

Frequently Asked Questions

How often should a hoist be inspected?

- Normal Service—yearly

- Severe Service—monthly to quarterly

- Special Service—as recommended by a qualified person

Intervals between inspection should never exceed one year. Written records are not required for frequent inspections, however written records should be kept. The WSTDA, RS-1 and ASME B30.9 require written record of the latest inspection.

Who can inspect a hoists?

All inspections shall be performed by a designated person per the manufacturer’s recommendations and with the requirements of ASME B30.21. Any deficiencies identified shall be examined and a determination made by a qualified person as to whether they constitute hazards and whether a more detailed inspection or disassembly is required.

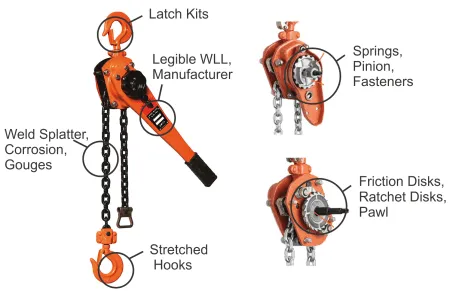

Common things inspectors recognize when inspecting a hoist?

Excessive component wear, cracks, distortion, warping, or other internal damage — or any other part that displays indications of potential failure — will be noted by the inspector. Based on that assessment, the hoist may be deemed beyond reasonable repair, and replacement is recommended.

Where can hoists be serviced?

Customers can come to one of our shops across the country or we can come to you with our Mobile Testing Unit. Technicians at Hercules SLR are trained and certified with LEEA accreditation. All inspections are completed within ASME standards.

What are signs of wear on hoist?

Excessive wear, corrosion, cracks, or distorted parts in the following:

- – Load blocks

- – Suspension housings

- – Hand chain wheels

- – Chain attachments

- – Clevises

- – Yokes

- – Suspension bolts

- – Shafts

- – Gears

- – Bearings

- – Pins

- – Rollers

- – Locking and clamping devices

- – Check hook-retaining nuts, collars, pins, welds, or rivets used to secure retaining members for excessive wear or damage.

- – Check load and idler sprockets, hand chain wheel, drums and sheaves for excessive wear and damage.

- – Check hand chain operated hoists for worn, glazed, or oil contaminated friction discs.

- – Check for worn pawls, cams and ratchets and corroded, stretched, or broken pawl springs in the braking mechanism.

- – Check support structure and trolley for damage.

- – Presence of legible warning labels.

- – Check end connection load chains for wear, corrosion, cracks, damage, or distortion

What should you do before you use a hoist?

If you’re a rigger, or have worked in construction, you’ve likely used some sort of hoist before. Hoists are mechanical devices use to lift, pull and hoist, and are equipped with a pulley. They’ve also been around for awhile—historians haven’t been able to pinpoint exactly when the first hoist was used, but even Leonardo da Vinci had a hoist design.

Since then, hoist technology has come a long way – hoists are available in manual, electric, hydraulic and even universal styles. They’re used in a number of different industries. Today, we cover more about hoists used for securing, lifting and rigging applications and what exactly you should do before you use one.

Hazard

We talk a lot about hazards, how to avoid them and prevent them on a job site. There are a number of hazards that present themselves at work – both chemical and physical. When rigging with hoists, there are a number of hazards there.

Some of the most common hazards are:

- Falling equipment, materials, etc.

- Electrical issues

- Loading hoist beyond it’s WLL or SLL, known as overloading

Training

It’s important that anyone using the hoist, or operating rigging equipment in general, has proper training in hoist safety and operating procedures. Hoists are often used in rigging, and are commonly-known as a component for cranes. Hercules’ highly-skilled trainers teach a variety of courses that will prepare you to rig with hoists.

The Hercules Training Academy courses include:

- Fundamentals of Rigging

- Fundamentals of Rigging (with Practical)

- Offshore Rigger Banksman

- Confined Space Entrant & Attendant (CSEA)

- Fundamentals of Overhead Cranes

- Overhead Crane Operato